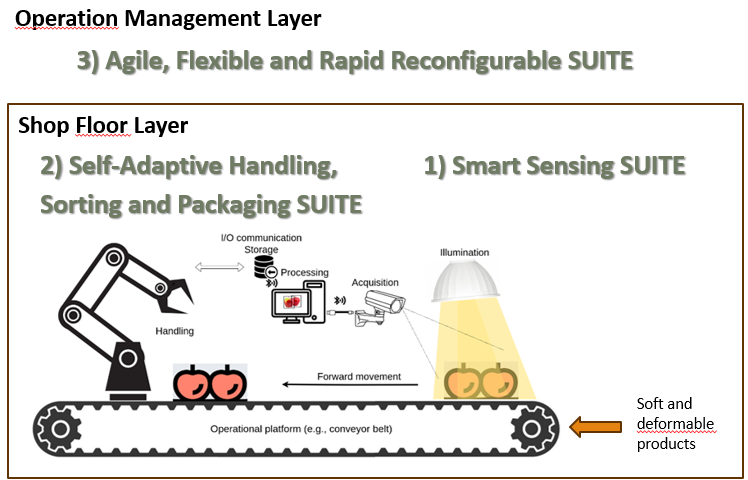

The AGILEHAND project has developed a comprehensive ecosystem of integrated technologies designed to revolutionize the handling, sorting, grading, and packaging of soft and deformable products in the manufacturing and agro-industrial sectors.

Through a modular approach, the project introduced three complementary suites combining advanced robotics, artificial intelligence, sensing technologies, and digital optimization tools into a cohesive, human-centric manufacturing framework.

The Smart Sensing Suite focuses on precise and non-invasive inspection of delicate products, using intelligent sensing technologies to assess both external features—such as shape, size, and colour—and internal quality factors like ripeness, texture, or softness. By providing reliable, real-time quality metrics, it ensures consistent grading and minimizes waste, even in demanding production environments.

The Self-Adaptive Handling, Sorting, and Packaging Suite enables flexible, automated manipulation of sensitive products through collaborative and autonomous robotic systems. It enhances productivity and safety by reducing human exposure to repetitive or risky tasks while maintaining gentle handling and high product integrity.

The Agile, Flexible, and Rapid Reconfigurable Suite introduces digitalization and smart decision-making into production management. Through real-time data analysis, digital twins, and optimization algorithms, it allows dynamic production reconfiguration, improved traceability, and resource efficiency, ensuring agile responses to changing market and operational needs.

Together, these suites form a complete, interoperable technology ecosystem that bridges AI, robotics, and human expertise, enabling manufacturers to build smart, flexible, and sustainable production lines. The AgileHand project thus paves the way toward a more resilient, efficient, and human-centric European manufacturing sector, aligned with the vision of Industry 5.0.