Agile, Flexible and Rapid Reconfigurable SUITE

The AGILEHAND Agile, Flexible, and Rapid Reconfigurable Suite is designed to improve the efficiency, adaptability, and resilience of modern manufacturing systems.

It provides an integrated set of digital tools that enable real-time optimisation, traceability, and reconfiguration of production lines.

By leveraging the digital twin paradigm, the suite allows for continuous monitoring, simulation, and optimisation of production processes, helping manufacturers react to changing market demands while maintaining productivity and quality.

The suite addresses key challenges in mixed-model production systems, from managing complex workflows to predicting deviations in process parameters such as temperature or material flow, and helps reduce inefficiencies, waiting times, and energy consumption across production lines.

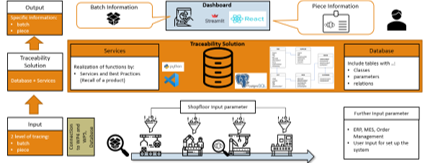

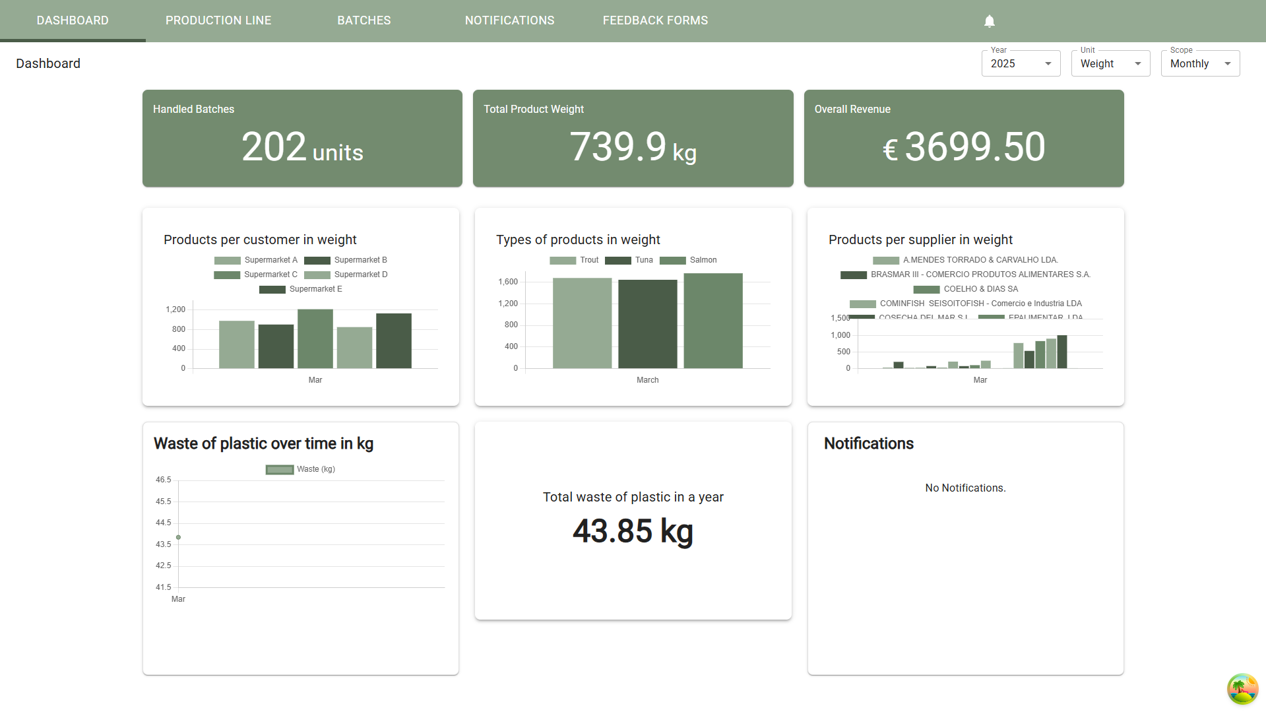

PTagile – Product-Oriented Traceability

PTagile provides a comprehensive traceability framework that collects and stores production and logistics data for each product order.

By linking operational information directly to individual products, PTagile ensures end-to-end visibility across the supply chain, enabling faster decision-making, improved quality assurance, and regulatory compliance.

This solution also integrates real-time monitoring dashboards, helping detect and address process deviations before they impact quality.

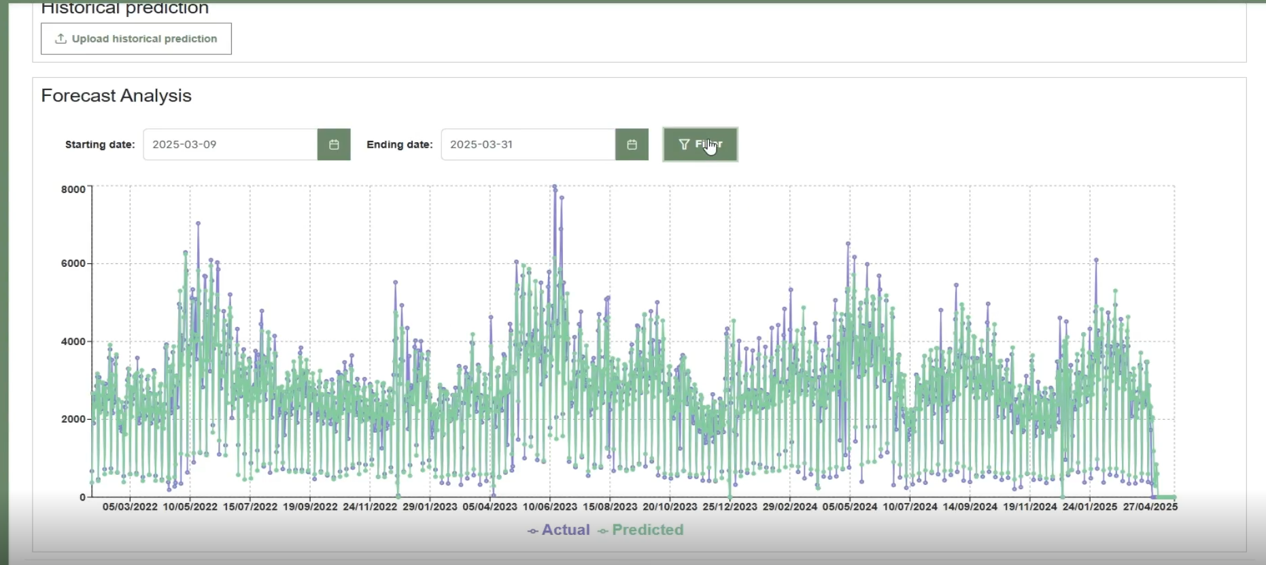

DTagile – Data-Driven Digital Twin

DTagile delivers a multi-layer digital twin environment that combines forecasting, optimisation, simulation, and analysis into a coherent framework.

It transforms production data into actionable insights, allowing operators to plan, simulate, and validate configurations before deployment.

By bridging real-time and predictive analytics, DTagile supports both daily operational decisions and long-term strategic planning.

PRagile – Production Reconfiguration

PRagile focuses on the automatic reconfiguration of production systems, optimising machine setups and line layouts to respond to product variability or unexpected events.

It reduces downtime and bottlenecks, improving operational agility while maintaining throughput and product quality.

PEagile – Production Execution Optimization Toolkit

PEagile integrates algorithms for production planning, scheduling, and process control, optimising resource allocation and startup sequences.

By supporting collaborative human-in-the-loop decision-making, it ensures a balance between automation efficiency and operator expertise.

The implementation of the Agile, Flexible, and Rapid Reconfigurable Suite is expected to bring significant improvements to production efficiency and operational resilience. By streamlining workflows and enabling intelligent reconfiguration, the suite can reduce waiting times in product queues by approximately 20% and improve product traceability across processing lines by up to 30%. It also contributes to a 15% reduction in material shortages and energy consumption through better planning and optimal line configuration. In addition, the system helps decrease order backlogs by 25% and shortens production programme makespan by around 15%, enhancing responsiveness to changing customer demands. Altogether, these advancements foster a more agile, efficient, and sustainable manufacturing environment that supports higher productivity, improved quality control, and reduced resource waste, fully in line with the Industry 5.0 vision of flexible and human-centric production systems.