Self-Adaptive Handling, Sorting and Packaging SUITE

The AGILEHAND Self-Adaptive Handling, Sorting, and Packaging Suite provides a new generation of intelligent robotic systems for the automated manipulation of soft and deformable products such as fish fillets, poultry, fruits, and vegetables.

This suite focuses on the development of physical systems and actuators capable of interacting delicately yet efficiently with products of varying sizes, shapes, and textures. Its technologies enhance flexibility, safety, and performance in industrial environments where high variability and product fragility are key challenges.

By combining advanced robotics, AI-driven adaptability, and collaborative systems, the suite enables rapid reconfiguration of production lines, reduces dependence on manual labour, and ensures consistent product quality.

An automatic smart grading system composed of 3 bricks:

- SThand: Self-Adaptable Transportation systems

- CRhand : Collaborative Robot

- RRhand: Robot-Robot

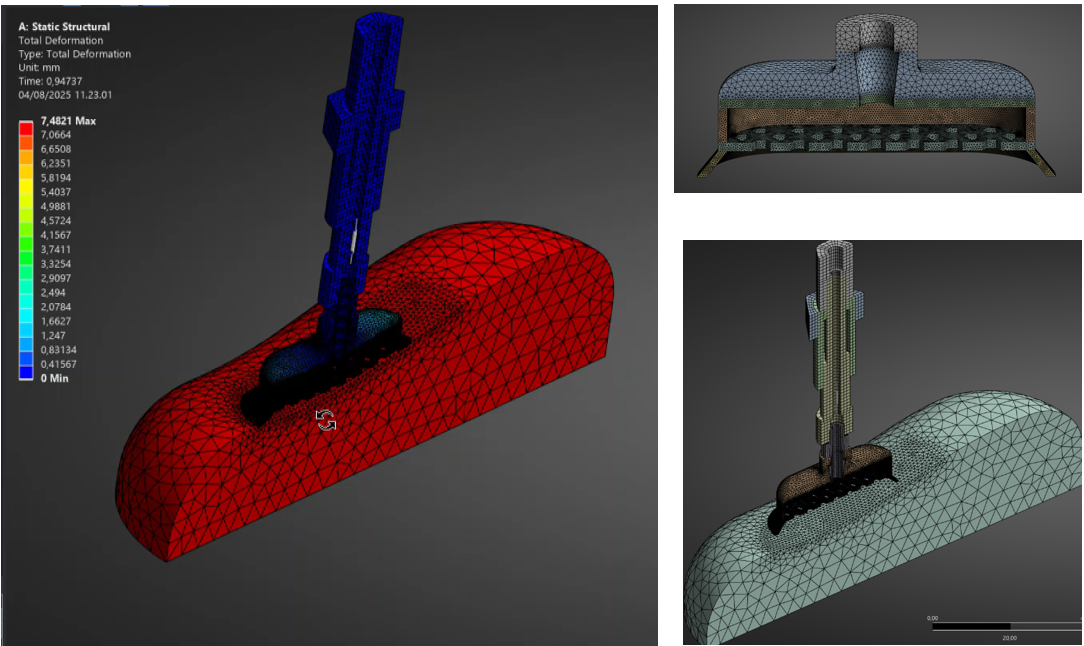

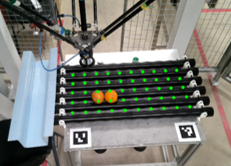

SThand – Self-Adaptable Transportation Systems

An intelligent, flexible platform for transporting, inspecting, and sorting delicate products. SThand adapts quickly to different product types with minimal hardware changes, improving efficiency, precision, and product quality while reducing waste. Perfect for dynamic, automated production lines in food and soft-product manufacturing.

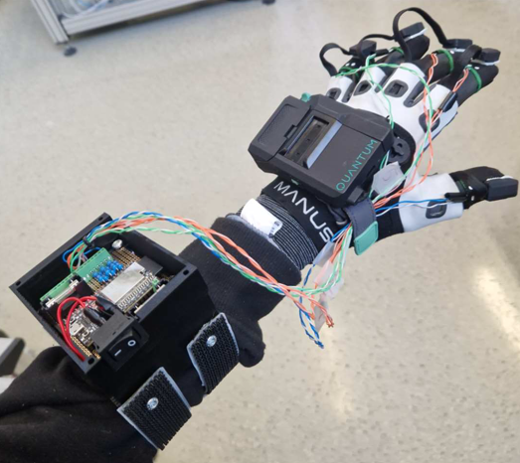

CRhand – Collaborative Robot

A next-generation collaborative robotic solution that enables safe human-robot cooperation in handling delicate products. CRhand reduces operator strain and risk while increasing accuracy, productivity, and consistency. Designed for ergonomic, human-centred workflows that merge automation with manual expertise.

RRhand – Robot-Robot Cooperation

A coordinated multi-robot system that ensures seamless communication and task sharing between machines on the production line. RRhand enhances speed, scalability, and reliability, creating smart, self-organising manufacturing environments aligned with the Industry 5.0 vision of adaptive, human-aware automation.

The introduction of the Self-Adaptive Handling, Sorting, and Packaging Suite is expected to bring substantial improvements in manufacturing flexibility, safety, and product quality. By integrating advanced robotics, collaborative systems, and intelligent automation, the suite allows for the precise manipulation of soft and delicate products, significantly reducing handling damage and ensuring consistent quality. Its self-adaptive and reconfigurable design enables faster transitions between product types, increasing the range of items that can be processed by up to 30% while reducing the risk of operator injuries through the automation of unsafe or repetitive tasks. The coordinated operation between collaborative and autonomous robots improves workflow efficiency and responsiveness, lowering downtime and production errors. Overall, this suite enhances productivity, workplace safety, and process reliability, contributing to a more human-centric and sustainable approach to modern manufacturing.