Smart Sensing SUITE

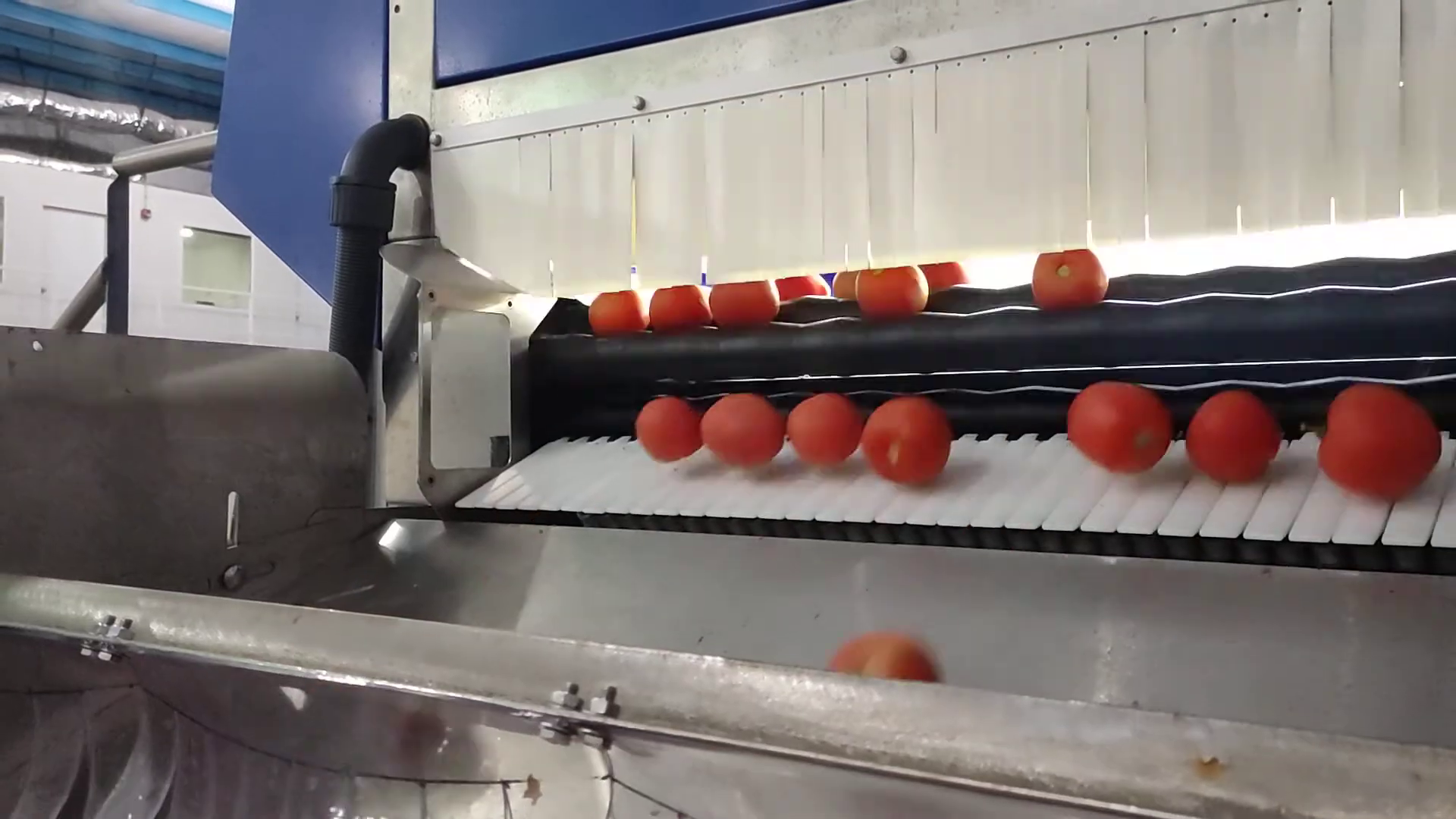

The AGILEHAND Smart Sensing Suite has been developed to provide precision scanning and quality assessment of delicate products, such as fish, chicken fillets, fruits, and vegetables,based on both their external appearance and internal characteristics.

Unlike traditional inspection systems, which focus primarily on visible features, this suite integrates multiple sensing technologies to evaluate shape, size, colour, and surface defects, as well as interior parameters such as ripeness, softness, and aroma indicators. This dual approach ensures a comprehensive evaluation of each product’s appearance and internal quality, which is essential for perishable goods.

The Smart Sensing Suite is designed to operate continuously and reliably in harsh industrial environments, 24 hours a day, 365 days a year. It provides a cost-effective and scalable solution for manufacturers aiming to improve product quality while reducing waste and energy consumption.

This automatic smart grading system is composed of 3 bricks:

• GQsens: Grading the Quality (interior & exterior)

• SCsens: Self Calibrating

• DSsens: Datasets (objects in real environment)

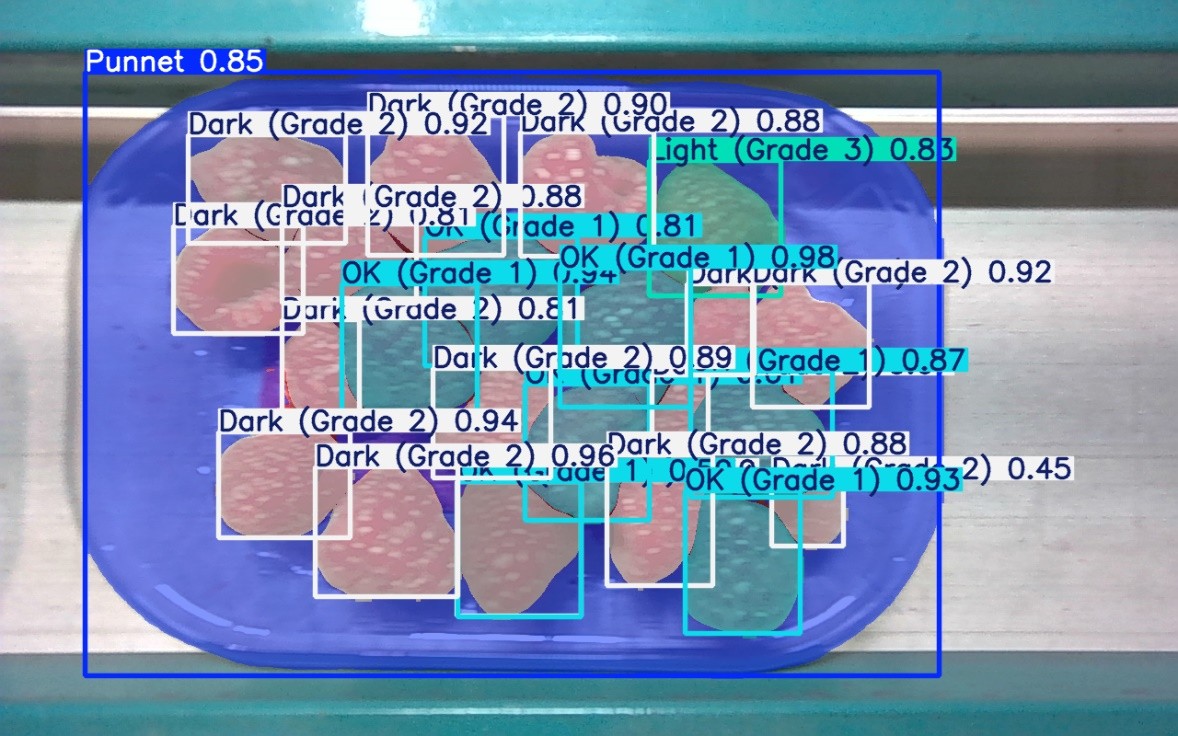

GQsens – Grading the Quality

A fast, accurate, and affordable solution to assess both the external and internal quality of delicate products. Using advanced imaging and AI analysis, GQSENS evaluates shape, colour, size, and ripeness in real time, reducing waste and ensuring consistent quality in agro-industrial production lines.

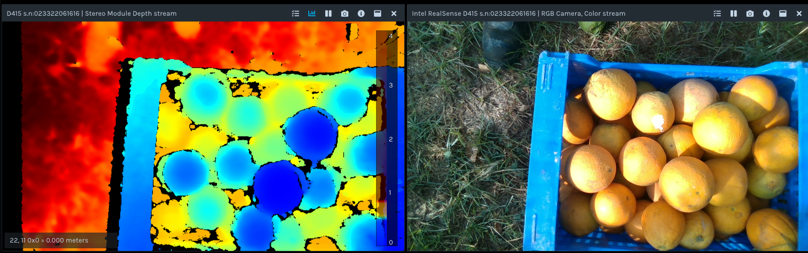

SCsens – Self-Calibrating Sensors

A smart, self-calibrating network of sensors that automatically adapts to production-line changes. SCSENS improves traceability, precision, and reliability, minimising manual adjustments and downtime. It keeps operations smooth and efficient, even in demanding 24/7 industrial environments.

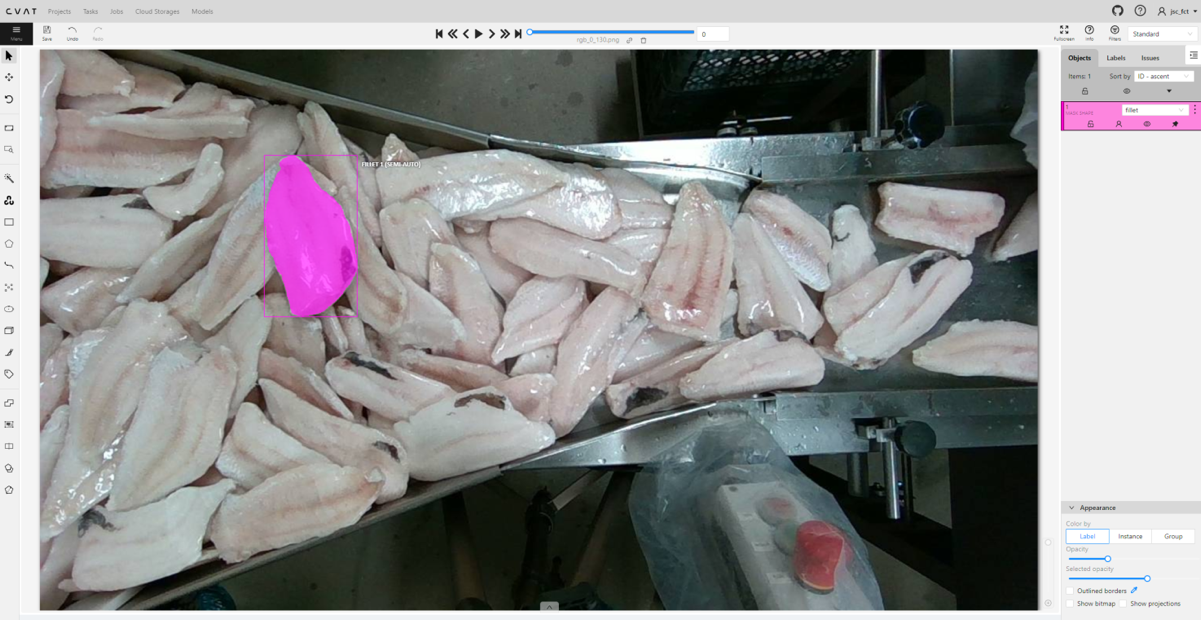

DSsens – Data Sets

A growing collection of real-world industrial datasets with high-quality scans and ground-truth data. DSSENS supports AI training, testing, and performance validation, enabling continuous improvement and faster adaptation of smart sensing technologies across different products and environments.

The implementation of the Smart Sensing Suite is expected to significantly enhance the quality, precision, and efficiency of product inspection and grading in manufacturing environments dealing with soft and delicate goods. By combining advanced sensing technologies with intelligent data processing, the suite enables faster and more accurate product scanning, increasing throughput by up to 25% while reducing product damage by around 20%. Its robust, self-adaptive design lowers energy consumption and ensures continuous operation, even in demanding industrial conditions. Beyond improving production speed and consistency, the suite also supports better decision-making through the generation of reliable quality metrics and data-driven insights. Overall, the Smart Sensing Suite delivers measurable gains in productivity, sustainability, and product integrity, contributing to safer, more efficient, and higher-quality manufacturing processes.